Powerful solutions that move your world.

Whether you want to go high or low: We have the right solution for you. Our control valves are customized to meet the needs of mobile machinery of all kinds – and always feature outstanding power density.

Different product series and their components allow new combinations and extensions – entirely according to your requirements. Whether cost, installation space or service requirements: We do our utmost to combine all the necessary functions to meet your machine requirements in the compact installation space of the control valve. In this way, for example, the installation and piping effort in your equipment can be minimized.

In addition to the new development of customer-specific performance features, we rely on a wide range of series-tested functional groups to ensure functionality. These are always arranged taking into account installation space and fluid technology requirements.

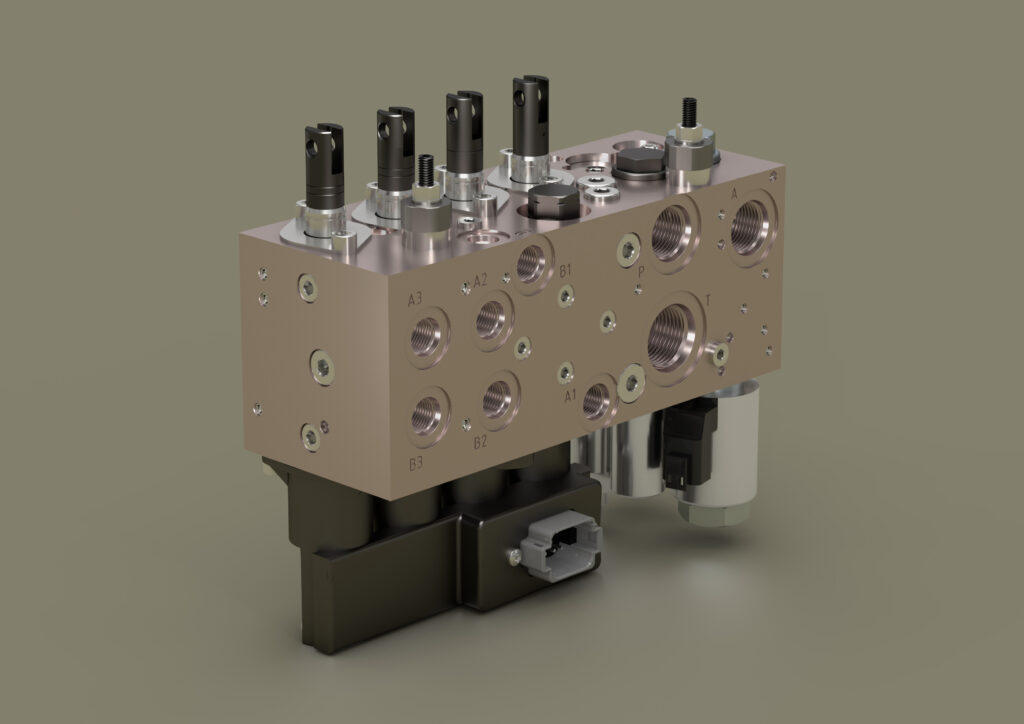

Our directional control valve blocks: Series after series a success

Height, length, width – we’ve got it figured out: the housings of our directional control valves comprise the overall circuit diagram for your task; between 20 and 200 elements ensure smooth interaction from the outside and the inside. On average, the entire package weighs twelve kilograms. In other words, a real powerful lightweight!

The three directional control valve block series VPS, PSS and MG are available in various size combinations and feature common strengths as well as individual characteristics, special features and added values. For example, all models are designed for controlling the working hydraulics of industrial trucks and other mobile applications – and can be used on machines with demand-controlled (PSS) as well as non-demand-controlled volume flow (VPS and MG).

As specialists, we ensure that our valves meet the requirements of your machines. Thanks to existing product series and series-tested components, we are also able to supply you with prototypes at short notice.

Series VPS

Series PSS

Series MG

Design and development: always at your side

The development process takes place in close cooperation with our customers. Together, we analyze the task and specifications while keeping an eye on both functional and economic aspects. To ensure the desired functionality, we rely on CFD, FEM and dynamic analyses as early as the design phase and also test the prototype in the vehicle jointly with you. If everything is to your satisfaction, we start series production – and deliver just in time!

Strong performance at a great price

Our economic production method is made possible by a highly automated and modern machine park combined with a high vertical range of manufacture and low overhead costs. Innovative production know-how, qualified and motivated employees as well as a sophisticated quality management ensure that we offer you smart and high-quality solutions at the best price-performance ratio. In addition, each of our end products is 100% hydraulically tested prior to delivery.